CalBox is the Leader in Wide Format Litho-Laminating with offset Printing

Wide Format Litho-Laminating and Printing

- We serve the retail, entertainment, and packaging industries by combing the strength of corrugation with fine quality offset litho-laminate printing.

- We provide full mount or spot litho labeling using three of the largest laminators and die cutters on the west coast.

- We can also litho-laminate or print our micro fluted durable corrugated board to resemble visually appealing, light-weight fluted folding cartons.

- With many different configurations and file sharing, CalBox can design innovative solutions requiring precise registration litho offset printing which is a complementory process with flexo and digital.

The future success of your business is what ultimately determines the degree of success of our business.

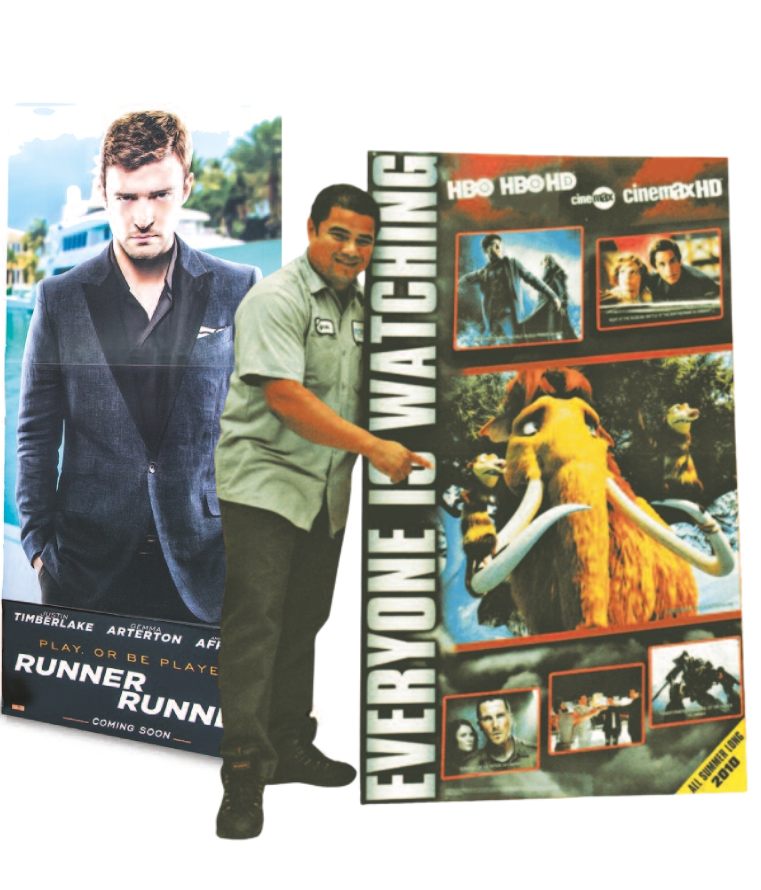

CalBox also designs and produces these 8-foot high movie displays

Quality, quantity and the skill of the operator are some of the common factors that are taken into consideration when deciding which is the right choice for a plant or job. Quality has been a point that many agree on.

Digital print though very good, often doesn’t achieve the level of quality that labeling can. If you’re looking for a nice, shiny, photo quality finish, labels are the way to go.

Quantities also play a role in determining the break even point of digital printing vs. labeling. For lower quantities and a desire for lower price, graphics would lead you to labels instead.

Cost is another factor that differentiates the two methods. The cost of ink, storing and maintaining ink, and maintenance costs are some reasons that customers have chosen to stick with labeling.

The labor costs can also be higher due to the skill needed to operate the printer. Customer tell us that they are using labelers instead of digital printers because of the trouble they have in finding skilled employees with the experience needed to run them.

CalBox Group

We are part of a Better Solution.